You are juggling several tasks. You are handling chaos. And you feel like your mind is a complete mess. I know—I’ve been there. But then I was introduced to the Kanban system, a method that helped me manage my many tasks through a straightforward visualization of task progress.

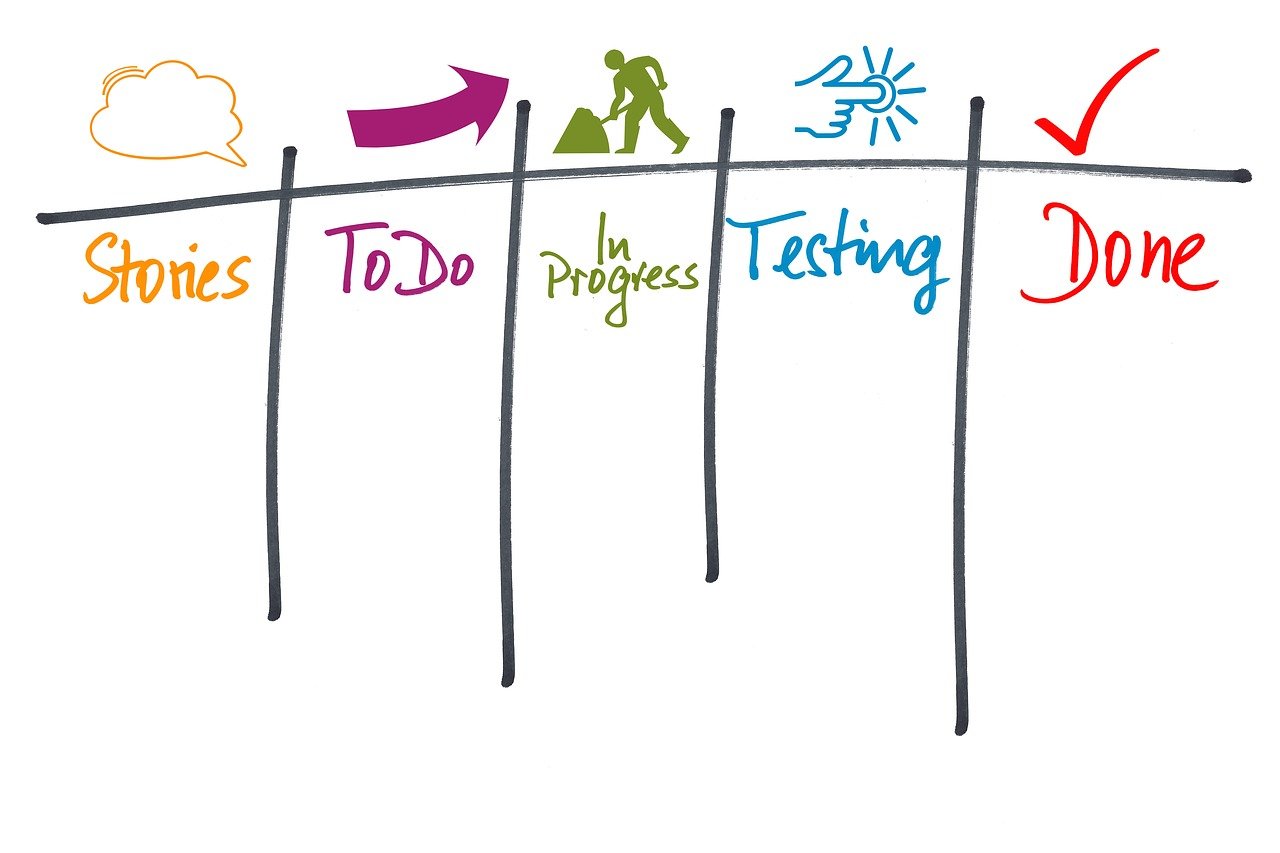

To put it simply, the Kanban system is to get a big board including different columns, such as "To Do", "In Progress", and "Done". By sticking different tasks under the different columns or even swim lanes, if the process is more complex, you can get a straightforward visual idea of how each project is going.

In this article

What Is Kanban?

The Kanban system started at Toyota in the 1940s, inspired by how supermarkets manage inventory. Just like supermarkets stock only what’s needed to meet demand, Kanban helps businesses dock production with actual consumption, avoiding shortages and excess inventory.

Today’s Kanban system revolves around a Kanban board, whether physical or digital. To set one up, the board should first outline every stage of your workflow, from beginning to end. This could include "To Do," "In Progress," and "Done," but feel free to tailor these to your needs. Then, you can map out your team's tasks on the Kanban board. Make sure your board highlights any obstacles or dependencies so you can resolve issues quickly if need be.

This is the standard general process; however, there are six specific types of Kanban, each designed for specific purposes. You can tailor your system by combining different types to meet your project’s requirements.

Six types of Kanban systems

Production Kanban

This is the most common and classic type of Kanban. It lists all tasks with their matching deadlines so you would know when and where to start. It also gives you crystal-clear information on both the quality and quantity of what needs to be made so that you can efficiently manage your materials. The production Kanban also indicates when to withdraw a card to keep your board simple.

Withdrawal Kanban

The withdrawal Kanban, also known as the conveyance Kanban, helps manage inventory by coordinating different production stages. It informs workers when a part is ready to move to the next stage and signals when to restock materials, showing the quantity needed and where to retrieve them. This ensures smooth supply chain operations, especially for products assembled from components made by different teams.

Supplier Kanban

The Kanban supplier is unique in integrating external suppliers into the system. Whenever you are low on stock, the supplier card goes straight to the supplier to safeguard your production. This streamlines purchasing, reduces the agonizing waiting time, and helps maintain consistent inventory levels.

Through Kanban

The through Kanban combines both the production Kanban and the withdrawal Kanban. It comes especially handy when collaborative production teams are geographically close to each other. In other Kanban systems, one team may receive a card to begin work, while another gets notified of incoming tasks. However, these two cards are combined through Kanban, allowing for faster transitions between stages and smoother operations.

Emergency Kanban

The emergency Kanban deals with situations out of the blue. In many cases, it informs workers of a malfunction or a change in product quantity. For example, if a problem is detected with the product, the emergency Kanban informs workers to prevent the issue from being replicated in production. If the problem is severe, it may even call the entire team to a halt so that no further waste would be produced before the issue is properly resolved. By highlighting urgent matters, the emergency Kanban can help you handle critical issues and prevent production delays.

Express Kanban

This type of Kanban is similar to Emergency Kanban but focuses more on the shortage of specific items. It helps maintain a constant process flow and avoids any slowdowns or stoppages.

Why Kanban?

Visibility:

The Kanban system provides a simple, straightforward visual overview of tasks, making it easy to track progress and identify and address bottlenecks in real time.

Productivity:

By visualizing the workflow, Kanban highlights inefficiencies, enabling smoother task completion. This improved flow increases productivity and helps you finish tasks faster.

Less waste:

The Kanban system minimizes production waste by optimizing time and resources to streamline processes and spot problems for necessary stops.

Increased predictability:

The Kanban system helps forecast by clearly stating the different stages and their progress. This creates a more predictable system and allows for better planning and trust-building with collaborative partners.

Closer collaboration:

By fostering transparency and clear communication, Kanban encourages teamwork. Teams can easily coordinate and adjust tasks to enhance collective efficiency.

Final words

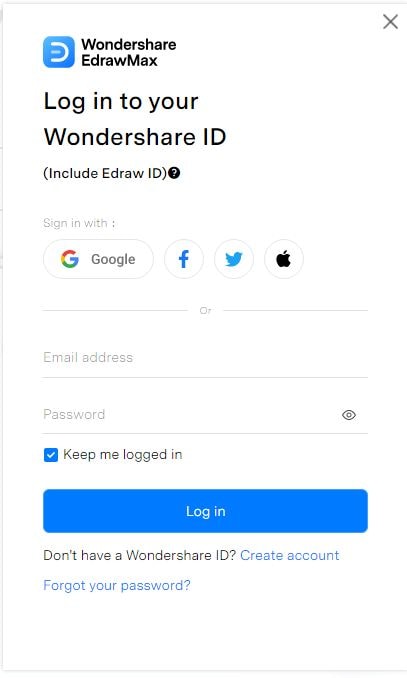

To produce your own Kanban system, there are several handy tools. Zoho Projects stands out with its customizable Kanban boards, making it suitable for diverse business needs and project sizes. Trello is another innovative Kanban-style collaborative platform that offers an intuitive interface with boards, lists, and cards, ideal for organizing tasks and enhancing team collaboration. Monday.com also supports Kanban views and is notable for its AI-driven features, allowing precise tracking and management of project timelines and dependencies.

If you want to try Kanban, pick one of these tools and start using it for your project today!